Flat Washer Installation General Instruction

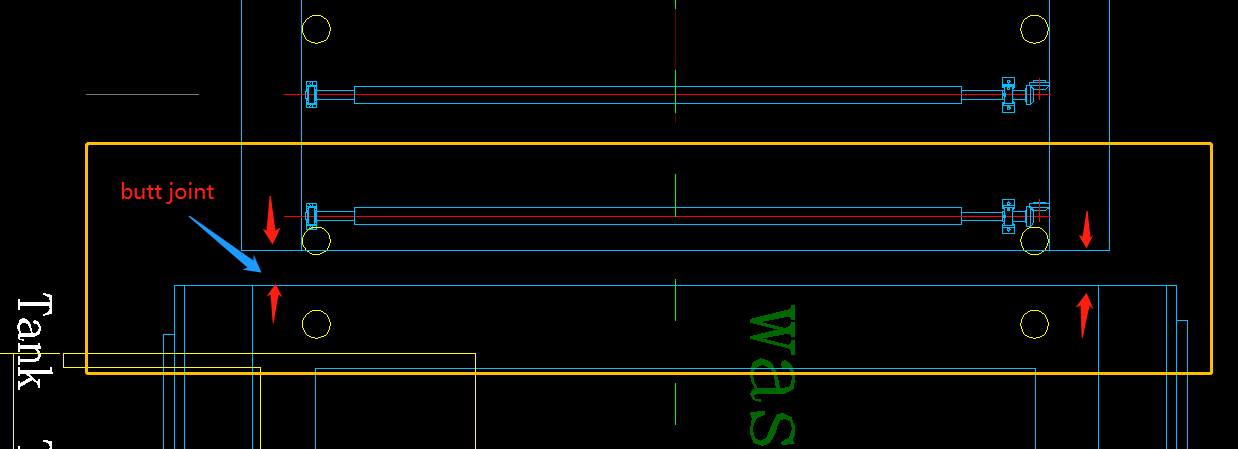

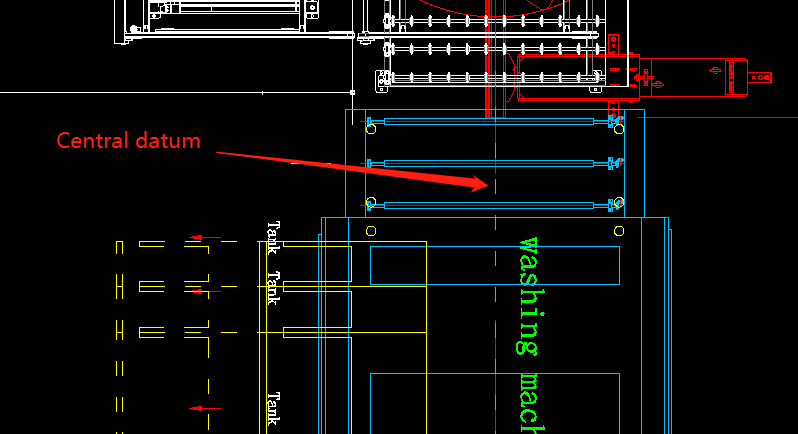

1. The center line of the rubber roller in the infeed conveyor is aligned with the center line of the front equipment. The horizontal line is connected, or according to the site's unilateral connection method.

2. After confirming the placement position of infeed conveyor, start to connect washing section to ensure that the horizontal line between infeed conveyor and washing section and the parallel line between the rubber rollers.

3. Drying section installation need to make sure the horizontal line between drying section and washing section and the parallel line between the rubber rollers.

4. Exit conveyor installation need to make sure the horizontal line between drying section and exit conveyor and the parallel line between the rubber rollers.

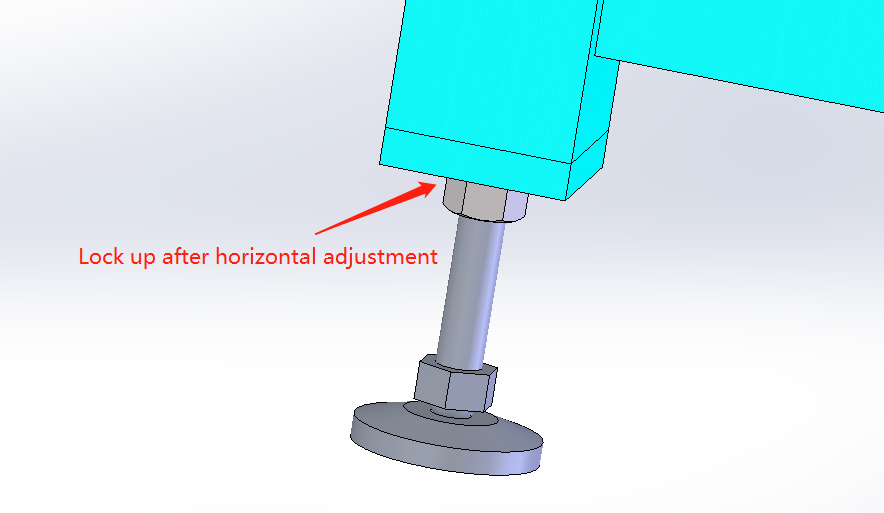

5. After the overall equipment is placed, fix the screws and pins on the bottom of the equipment. After fixing, perform horizontal line measurement to confirm.

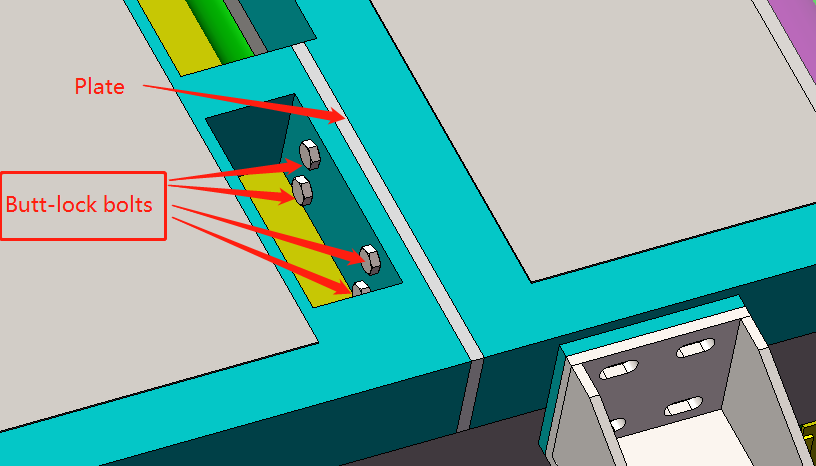

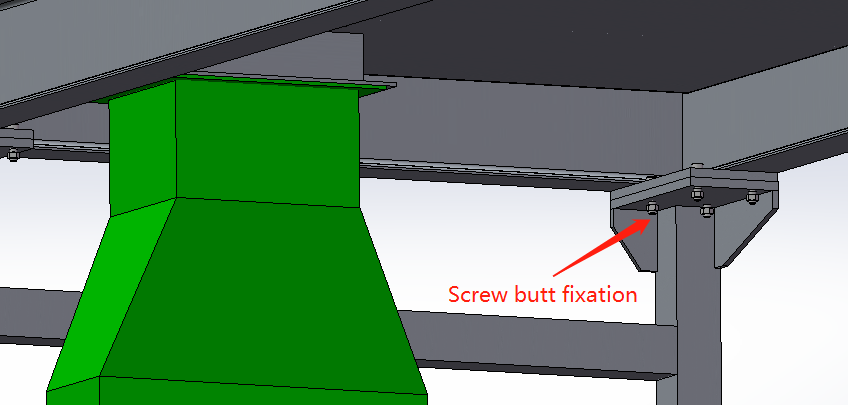

6. The connection of upper frame between washing section and drying section is based on the docking of all the screws and pin holes of upper frame. After connection, measure whether the distance between the upper and lower frame is consistent (measured according to 6 lifting screws and 6 directions).

7. After connection of the whole equipment is completed, the drive shaft connection is performed. During the connection, make sure lifting screw shaft without rotation to ensure the distance between upper frame and lower frame will not change.

8. The fan chamber is docked and fixed according to the upper and lower screw holes.

9. The water tank is placed according to 1.2.3. Water tank accessories such as pressure gauges and filters are included in the accessories box.

10. Install ducts of air knife after installing the protective cover of the whole machine.

11. The electrical cabinet is connected and fixed according to the electric wire and the electrical cabinet wire number.

12. Water supply to the water tank (water pump operation is strictly prohibited under no water condition), and gas connection to the equipment.

13. Power on the test machine, and you need to manually perform all steps of the equipment to test the normal operation before you can switch to automatic mode

a. Check whether all motors are running normally during manual operation.

b. Whether the drive shaft runs smoothly.

C. Whether the lifting is normal and the fan Etc. should be confirmed after trial production.

Post time: Jul-03-2021